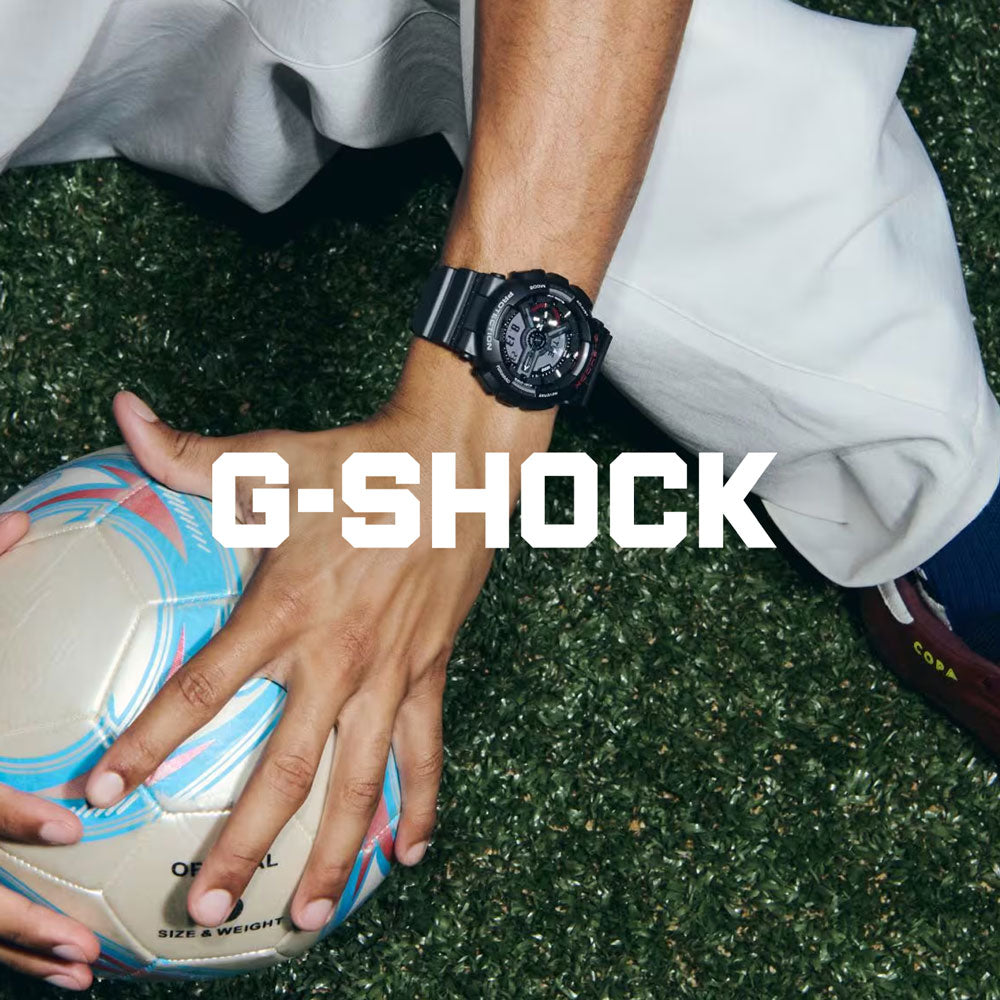

The authoritative statement of structural beauty, created with diverse materials and innovative layered-composite band

All-new structure employing a frame made with combined materials

Multi-layered carbon frame: Layers of toughness interwoven with beauty

Layered-composite band: Creating a new form of structural beauty

Meticulous finishes for a look of solidity and radiance

Dial design with sharpness and depth exuding intricacy

Triple G Resist