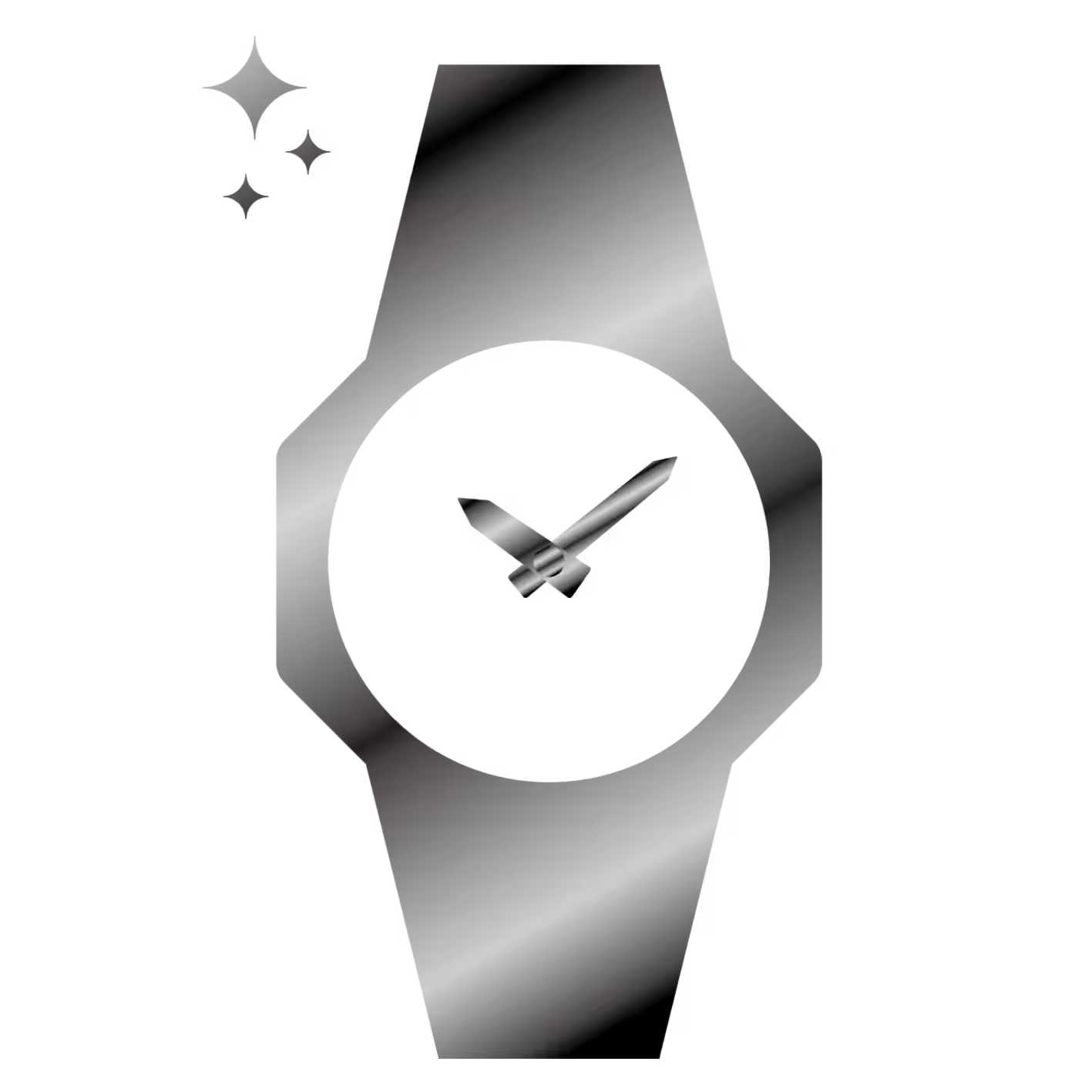

Multiple processes are employed to achieve the distinctive structural beauty of the metal bezel. First, the intricate form inherited from the very first G-SHOCK is crafted with forging. Details evoking industrial product design are then added: a finely uneven texture pressed to the top surface, and openings cut into the lug portions. The entire exterior of the timepiece is honed to create a matte finish, and a hairline finish is then applied to the sides to enhance the texture of the metal while tempering the shine.

In addition, a black IP surface finish offering superior abrasion resistance is applied to the GM5600BM and GM2100BM. After the entire exterior is coated, the finish is partially removed from the top surface to expose the stainless steel beneath. The process creates a chic impression, adding depth to the bezel and a unified look.